Brickwork lintels play a crucial role in the structural integrity of buildings. A brickwork lintel is a horizontal support placed above doors, windows, and other openings to ensure stability and even load distribution. These lintels are essential for preventing structural failures and maintaining the overall strength of a building. Whether you are constructing a new home or renovating an existing structure, understanding the importance and proper maintenance of brickwork lintels is vital. This guide will help you comprehend the different types of lintels, their installation process, and common issues associated with brickwork lintels.

Table of Contents

What is a Brickwork Lintel?

A brickwork lintel is a horizontal structural element made from bricks or other materials, used to support the weight above openings like doors and windows. These lintels distribute the load to the adjacent masonry, preventing structural failure. Lintels are essential in ensuring that the weight from the walls above does not cause the openings to collapse or crack.

Why Are Lintels Important?

Lintels are vital because they provide structural support, preventing damage to buildings. Without a properly installed lintel, the weight above an opening could cause the masonry to bow or crack, leading to significant structural issues over time.

Types of Brickwork Lintel

There are several types of lintels used in brickwork, each with its unique characteristics and applications.

Here’s a detailed look at the different types of brickwork lintels:

1. Steel Lintels

Steel lintels are widely used due to their strength and durability. They are often prefabricated, making them easy to install in various construction projects.

- Strength and Durability: Steel lintels are known for their ability to bear heavy loads, making them suitable for both residential and commercial buildings.

- Prefabrication: These lintels are typically made off-site and delivered ready for installation. This reduces the time and labor required on-site.

- Versatility: Steel lintels can be used in various construction styles and are compatible with many building materials.

- Corrosion Resistance: Many steel lintels are treated or coated to resist corrosion, ensuring a long lifespan even in harsh environments.

- Aesthetics: Proper finishing allows you to incorporate steel lintels seamlessly into the design of a building, offering both functionality and visual appeal.

2. Concrete Lintels

Manufacturers make concrete lintels from reinforced or prestressed concrete, providing excellent load-bearing capacity. Builders commonly use them in modern construction.

- Reinforced Concrete: Contains steel bars to enhance strength and prevent cracking.

- Prestressed Concrete: Made by tensioning the steel reinforcement before casting, which improves load-bearing capacity.

- Load-Bearing: Ideal for supporting substantial weights and spans, making them suitable for large openings.

- Durability: Concrete lintels are resistant to weathering and can last for decades with minimal maintenance.

- Versatility: Can be customized to fit different architectural styles and sizes.

3. Brick Lintels

Brick lintels are constructed using bricks and mortar, blending seamlessly with brick walls. They are best suited for smaller openings.

- Construction: Built by laying bricks in a specific pattern and bonding them with mortar.

- Aesthetics: Match the surrounding brickwork, providing a uniform appearance.

- Cost-Effective: Typically cheaper than other lintel types, especially for small projects.

- Limitations: Not suitable for supporting heavy loads or large spans.

4. Stone Lintels

Stone lintels have historical significance and are aesthetically pleasing, often used in traditional and heritage buildings.

- Materials: Typically made from natural stone like sandstone, limestone, or granite.

- Aesthetics: Offer a timeless, classic look that enhances the appearance of traditional buildings.

- Craftsmanship: Require skilled craftsmanship for proper installation.

- Durability: Extremely durable and weather-resistant, suitable for long-term use.

- Cost: More expensive due to the material and labor involved in installation.

5. Timber Lintels

Timber lintels are made from hardwood or treated timber and are used in older buildings and some modern applications.

- Materials: Typically made from high-quality hardwoods or treated softwoods to resist decay.

- Aesthetics: Provide a natural, warm appearance that blends well with timber-framed buildings.

- Insulation: Timber lintels offer better thermal insulation compared to metal or stone.

- Maintenance: Require regular maintenance to prevent rot and termite damage.

- Limitations: Less suitable for heavy loads and large spans, and have a shorter lifespan compared to other lintel materials.

Installation of Brickwork Lintel

Installing a brickwork lintel involves several steps to ensure structural integrity and safety.

Here’s a detailed breakdown of the process:

1. Preparation

- Measure the Opening Accurately: Before starting, measure the width and height of the opening where you will place the lintel. This ensures you select the right size and type of lintel for the job. Accurate measurements prevent future structural issues and ensure a proper fit.

- Choose the Appropriate Lintel Type: Based on the load and span requirements, select the lintel that best suits your needs. Consider factors like the weight it needs to support and the environmental conditions it will be exposed to. Common types include steel, concrete, and timber lintels, each offering different benefits.

2. Setting Up

- Create Temporary Supports: To hold the masonry above the opening, use temporary supports like acrow props or wooden beams. These supports prevent the structure from collapsing during the installation. Position the supports securely on either side of the opening to bear the weight of the masonry above.

- Ensure Supports Are Secure: Double-check that all temporary supports are stable and securely in place before proceeding. This step is crucial for the safety of the construction process. Any movement or instability in the supports can lead to dangerous working conditions and potential structural failure.

3. Placing the Lintel

- Position the Lintel Above the Opening: Carefully lift and place the lintel into position above the opening. Make sure it fits snugly between the supports. It’s important to handle the lintel with care to avoid any damage during placement.

- Check for Levelness and Alignment: Use a spirit level to ensure the lintel is level and aligned correctly. This step is vital to avoid any future structural issues. Misalignment can lead to uneven load distribution and potential cracking or sagging.

4. Securing the Lintel

- Use Mortar or Other Adhesives: Apply a layer of mortar or a suitable adhesive to the bed where the lintel will rest. This helps to secure the lintel in place and provides additional stability. Evenly spread the adhesive to ensure full contact and bonding with the lintel.

- Allow the Mortar to Set: Before removing the temporary supports, allow the mortar to set and harden properly. This ensures the lintel is firmly secured and can bear the load of the masonry above. Depending on the type of mortar used, this setting time can vary, so follow the manufacturer’s recommendations.

5. Finishing

- Complete the Brickwork Around the Lintel: Once the lintel is in place and the mortar has set, complete the brickwork around it. Ensure the bricks are laid uniformly and match the existing masonry. This step integrates the lintel into the structure seamlessly.

- Ensure the Masonry is Consistent and Well-Integrated: Take care to blend the new brickwork seamlessly with the surrounding structure. This not only improves the aesthetic appeal but also enhances the overall strength and stability of the building. Consistent brickwork evenly distributes the load and prevents future structural issues.

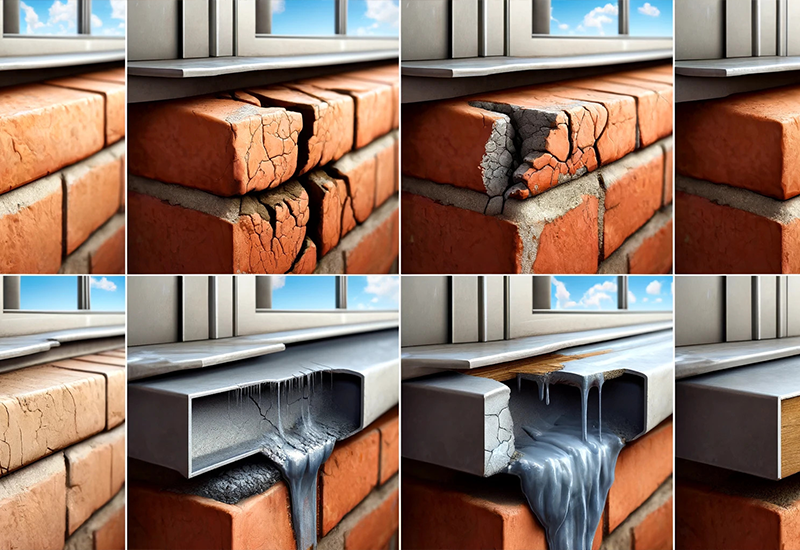

Common Issues with Brickwork Lintels

Despite their durability, brickwork lintels can encounter several problems. Identifying these issues early and addressing them promptly is crucial for maintaining the structural integrity of a building.

1. Cracking

- Causes: Excessive load or poor installation often causes cracking in brickwork lintels. A lintel can develop cracks when subjected to a load greater than its capacity. Similarly, incorrect installation can create stress points, leading to cracks.

- Impact: Cracks can compromise the structural integrity of the building, leading to potential safety hazards. If not addressed, cracks can expand, causing more significant damage to the masonry and the overall structure.

- Prevention and Repair: Regular inspections can help detect cracks early. If you find cracks, assess the extent of the damage. You can repair minor cracks with appropriate sealants, while more significant damage may require replacing the lintel.

2. Corrosion

- Causes: Corrosion primarily affects steel lintels. Exposure to moisture and environmental conditions can lead to rusting and weakening of the steel. Poor maintenance and lack of protective coatings can accelerate this process.

- Impact: Corrosion weakens the lintel, reducing its load-bearing capacity. Over time, this can lead to structural failure, posing serious safety risks.

- Prevention and Maintenance: Regular inspection and maintenance are crucial. Applying protective coatings and ensuring proper drainage around the lintel can help prevent corrosion. If you detect corrosion, treat or replace the affected lintel promptly.

3. Sagging

- Causes: Inadequate support or improper installation causes a lintel to sag. Insufficient temporary supports during installation can cause the lintel to settle unevenly, leading to sagging.

- Impact: Sagging can cause structural damage, including cracks in the surrounding masonry and misalignment of doors and windows. It can also affect the aesthetic appeal of the building.

- Prevention and Repair: Ensuring proper support during installation is key to preventing sagging. If you detect sagging, install additional supports or replace the lintel to restore structural integrity.

4. Water Damage

- Causes: Water damage is a common issue for timber and stone lintels. Exposure to moisture can lead to rot in timber lintels and deterioration in stone lintels. Poor sealing and lack of maintenance can exacerbate these issues.

- Impact: Water damage can significantly weaken lintels, reducing their effectiveness and potentially leading to structural failure. Rotting timber can lose its load-bearing capacity, while deteriorating stone can crumble and crack.

- Prevention and Maintenance: Proper sealing and regular maintenance are essential to prevent water damage. Ensuring good drainage around lintels and applying protective treatments can help protect them from moisture. If you detect water damage, repair or replace the affected lintels promptly.

Table of Common Issues and Solutions

| Issue | Causes | Impact | Prevention and Solutions |

| Cracking | Excessive load, poor installation | Compromises structural integrity, safety hazards | Regular inspections, use of sealants, replace if necessary |

| Corrosion | Exposure to moisture, poor maintenance | Weakens lintel, potential structural failure | Protective coatings, proper drainage, treat or replace corroded lintels |

| Sagging | Inadequate support, improper installation | Structural damage, misalignment of openings | Ensure proper support, additional supports or replacement |

| Water Damage | Exposure to moisture, poor sealing | Weakens lintel, structural failure | Proper sealing, regular maintenance, repair or replace affected lintels |

Maintaining Brickwork Lintels

Regular maintenance is essential to ensure the longevity and effectiveness of brickwork lintels. Proper maintenance helps to prevent structural issues and extends the life of the lintels.

Here’s a detailed look at how to maintain brickwork lintels effectively:

1. Inspection

- Periodic Checks: Conduct regular inspections to check for cracks, corrosion, and other issues. Perform inspections at least annually, and more frequently in areas with harsh weather conditions. Look for signs of wear and tear that could indicate potential problems.

- Immediate Action: Address any problems immediately to prevent further damage. Early detection and repair of issues such as cracks or rust can prevent more significant structural problems down the line. Use tools like magnifying glasses and flashlights to spot minor defects that the naked eye might miss.

2. Cleaning

- Removing Debris: Keep lintels free from debris and vegetation. Debris can trap moisture against the lintel, leading to deterioration, especially in timber and stone lintels. Use a brush or a gentle pressure washer to clean the surface.

- Appropriate Methods: Use appropriate cleaning methods for different lintel materials. For instance, use a mild detergent solution for most materials, but avoid harsh chemicals that could damage the lintel. Stone lintels may require specific cleaning agents that do not erode the stone.

3. Repairs

- Fixing Minor Issues: Fix minor issues promptly to avoid extensive repairs later. Address small cracks or surface rust with sealants or anti-rust treatments. Ensure that the materials used for repairs are compatible with the lintel.

- Professional Help: Consult professionals for significant damage or complex repairs. If a lintel shows extensive cracking, sagging, or severe corrosion, it’s best to call in experts. They can assess the damage accurately and provide the most effective solutions.

4. Sealing

- Preventing Water Ingress: Apply sealants to prevent water ingress in stone and timber lintels. Water can cause significant damage over time, leading to rot in timber and erosion in stone. Sealants create a protective barrier that keeps moisture out.

- Reapplication: Reapply sealants as needed based on manufacturer recommendations. Sealants can wear away over time, especially in exposed areas. Regular reapplication ensures continuous protection. Keep track of when you last applied sealants and follow a maintenance schedule.

Table of Maintenance Activities

| Maintenance Activity | Description | Frequency | Tools/Materials Needed |

| Inspection | Check for cracks, corrosion, and other issues | Annually or more frequently in harsh conditions | Magnifying glass, flashlight |

| Cleaning | Remove debris and vegetation, use appropriate cleaning methods | Every 6 months or as needed | Brush, mild detergent, pressure washer |

| Repairs | Fix minor issues promptly, consult professionals for major repairs | As soon as issues are detected | Sealants, anti-rust treatments, professional services |

| Sealing | Apply and reapply sealants to prevent water ingress | Based on manufacturer recommendations | Sealants, application tools |

Conclusion

Understanding brickwork lintels is crucial for any construction project. Proper maintenance and regular inspections can extend the life of a brickwork lintel and prevent structural issues. If you notice any problems, it’s essential to address them promptly to maintain the integrity of your building. For those seeking professional assistance with brickwork lintels, consulting a skilled contractor is the best approach. If you need expert help with your brickwork lintel, contact us at +(1) 917-477-9667 for reliable and professional service.

FAQs

Q: What is a brickwork lintel and why is it important?

A: Builders install a brickwork lintel as a horizontal support structure above openings like doors and windows. It is important because it distributes the load from the masonry above, preventing structural failures and ensuring the stability of the building.

Q: How often should a brickwork lintel be inspected?

A: A brickwork lintel should be inspected at least once a year. Regular inspections help identify potential issues such as cracks or corrosion early, ensuring the lintel remains in good condition and maintains the structural integrity of the building.

Q: Can I install a brickwork lintel myself?

A: You can install a brickwork lintel yourself, but we recommend hiring a professional. Proper installation ensures the lintel’s effectiveness and safety. A professional contractor has the expertise to install the brickwork lintel correctly.

Q: What common problems are associated with brickwork lintels?

A: Common problems with brickwork lintels include cracking, corrosion, sagging, and water damage. These issues can compromise the lintel’s ability to support the load and may lead to structural failures if not addressed promptly.

Q: How can I maintain a brickwork lintel to ensure its longevity?

A: To maintain a brickwork lintel, conduct regular inspections, clean it to remove debris and vegetation, repair minor issues promptly, and apply sealants to prevent water ingress. Regular maintenance will help ensure the longevity and effectiveness of the brickwork lintel.